A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Design tips for screed over UFH

Design tips to prevent disruption to flooring due to movement of screeds in heated floors

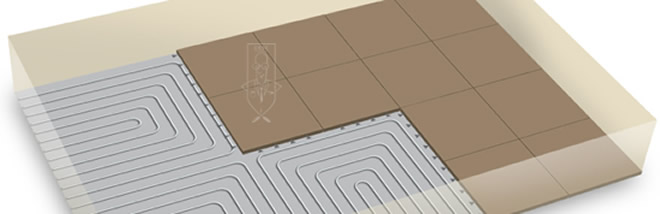

Unlike normal screed constructions, heated screeds (screeds laid over under floor heating) require certain special design considerations. As the heating elements for the under floor heating system are embedded in the screed, chances are high for the screed to develop potential serviceability problems, unless appropriate stress relief measures are incorporated right at the design phase.

Disruption to flooring due to constant screed movements is one of the most common problems encountered in heated screeds. Movement of the screeds is however inevitable and will continue throughout the life of the floor as heated screeds follow the ‘floating screed construction’ (where the screed is isolated from the base by a layer of thermal insulation). This construction is adopted to retain efficiency and prevent heat from escaping through the base. However, the isolation of the screed from the base facilitates the screeds to realize their full movement potential as the screeds expand and contract with the change in temperature of the heating elements.

But as it is not practically possible to restrict these movements altogether, the best recommended option is to design the screed in such a way as to fully accommodate the movements to prevent disruption to the screed and the flooring.

But as it is not practically possible to restrict these movements altogether, the best recommended option is to design the screed in such a way as to fully accommodate the movements to prevent disruption to the screed and the flooring.

DIN 18560 Part2 lays out some specific recommendations to be adopted at the design stage for heated screeds:

- Limit bay size to 40 sq.m

- Limit maximum bay dimension to 8m

- Coordinate bay sizes with individual heating circuits

- Provide complete isolation for bay joints

- Isolate perimeters and projections with joints capable of a movement of at least 5mm

- Cut down the number of elements passing through the joints

- Keep the heating elements isolated and accurately align elements passing through the joints

- For cementitious screeds, introduce additional stress relief joints

- Provide reinforcement for cementitious screeds where rigid flooring is to be applied

As manufacturers or suppliers generally tend to focus on guidance pertaining to the mechanical side of installation alone, it is always advisable to seek specialist advice while going for under floor heating systems.