A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Surface Regularity of screeds for normal accuracy flooring

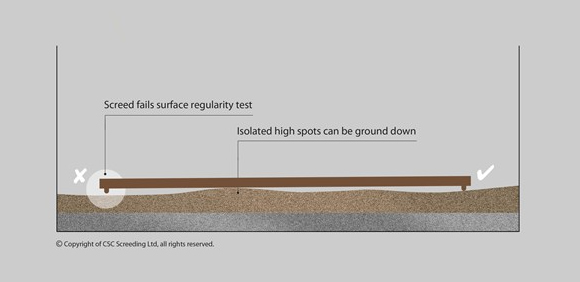

Surface Regularity Fail

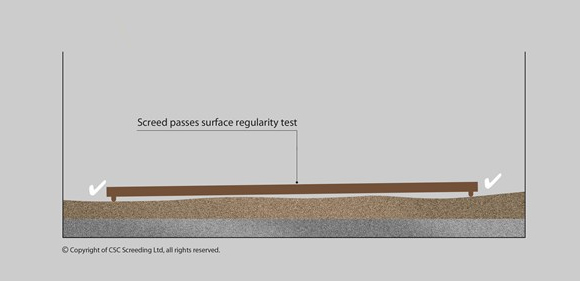

Surface Regularity Pass

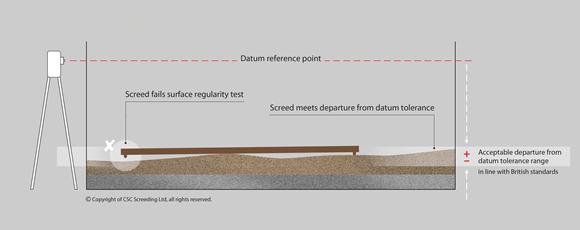

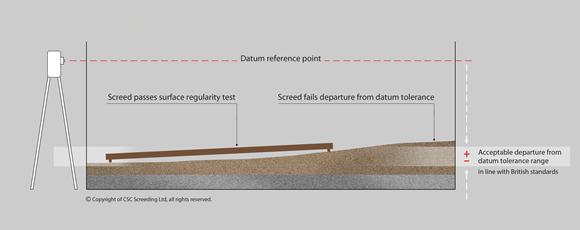

Surface regularity is an important quality of a screed or floor surface, which is often described as a measure of waviness of the surface. For normal accuracy floors, it is defined as the limitation of deviation of the surface beneath a straightedge laid flat on the surface.

Given below is the general surface regularity classification for normal accuracy floors (Excerpt, CIRIA Report 184):

Surface Regularity speciation of screeds for normal accuracy floors

| Classification | Usage |

| SR1 | High Standard |

| SR2 | Normal Standard |

| SR3 | Utility Standard |

As per the British Standards Code of Practice, the surface regularity of screeds for normal accuracy floors are measured based on the deviation from a straightedge laid flat on the surface. And the deviations are measured between the points which are in contact with the floor surface, from the underside of the straightedge using a slip gauge or other suitable accurate measuring device.

However, the code dictates different specifications based on the type of screed and final floor finish, and it is important to ensure that the method of measurement is in abidance with the particular specification.

Regularity Fail Datum Pass

Regularity Pass Datum Fail

BS Code of Practice recommendations on measurement of Surface Regularity of screeds for normal accuracy floors ( Excerpt, CIRIA Report 184):

| Type of screed or base | Measurement Criteria |

| Screeds to receive applied flexible floorings |

BS8203. 2-m straightedge laid in contact with the screed Maximum gap measured with a slip gauge SR1 3mm SR2 5mm SR3 10mm |

| Screeds to receive toppings or in situ applied floorings |

BS8204 Part1. 2-m straightedge laid in contact with the screed Maximum gap measured with a slip gauge SR1 3mm SR2 5mm SR3 10mm |

| Screeds to adhesive fixed rigid tile applied floorings |

BS5385 Part3. 2-m straightedge laid in contact with the screed Maximum gap measured with a slip gauge SR1 3mm SR2 5mm SR3 10mm |

| Screeds to receive timber flooring | BS8201. Localized variations in level should not exceed +/-3mm from the mean when measured over a 2-m distance using a straightedge |

Remedial measures in case of non-compliance

Remedial measures in case of non-compliance generally include localized grinding (where the effect on appearance is not an issue). For toppings like ceramic flooring and natural stone, the most feasible option would be localised grinding or application of smoothing compounds. For cases where the screed is too high it might be necessary to remove and replace the affected area.

However, before resorting to any major remedial measures it is best to compare the degree of non-compliance and its effect on the final flooring against the possible costs, delays and effect on appearance.