Always make sure that the moisture tests are conducted

You had the most expensive carpets imported, and got the best screed contractors to work on your floors. But, after all the work is done you notice the final finish is not quite up to the mark and the flooring lacks the ‘perfect finish’ you hoped to see. What could possibly have gone wrong?

Even the best of floor finishes can fail if they are laid on before the screed is dry enough to take the sensitive finishes. And the reason- ‘excessive moisture’- most of the time! The benchmarks for drying time may vary with screeds. But, it is extremely important to ensure that the moisture content of the screed is tested accurately and on time using a reliable moisture testing method. And also make sure that the results are recorded strictly before going on to lay the final finish.

The recent failure of the screeding project at Uxbridge College is an example of what can cause a floor finish to fail.

Case Study: Uxbridge College, March 2011

A screeding contractor was handed the project to screed the new sports hall and changing area at Uxbridge College using FlexiDry F2/14 day dry on behalf of the Principal Contractor.

Sports Hall

When a moisture test was conducted on the screed in the main sports hall at the end of a 13 day drying period, the screed was found to have a higher moisture level than expected. It is to be noted that the screed used was a FlexiDry F2/14 which should ideally have been tested for moisture levels on day 15. However, under pressure to come up with a quick solution, the Principal Contractor finally recommended that a DPM be applied on the 650sm area. As the application of DPM is much more expensive than screeding itself, the decision of the contractor brought on substantial unnecessary expenditure to the client due to a seemingly minor error of judgment on the contractor’s part.

Changing Areas

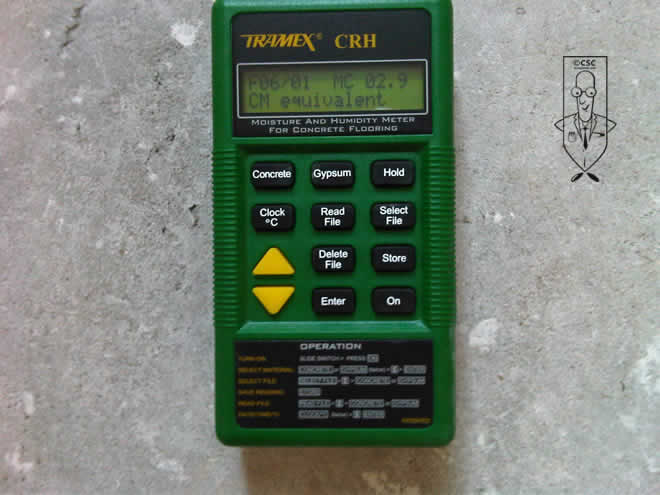

It was found that the vinyl finish in the changing area had bubbled and lifted. Subsequently, the vinyl was removed to examine the substrate, and upon inspection it was seen that the adhesive had become wet and milky. So, it was decided to conduct a Tramex moisture test in the presence of the Screed Manufacturer, the Principal Contractor, Floor Screeding Contractor and the Floor Finishing Contractor. The tests showed that the screed was a CM 1.6%, the latex 3%, and the adhesive was quite wet.

However, the screed was found to be dry. The problem could therefore have been due to a number of reasons from- applying the vinyl when the latex had still been wet, faults of the adhesive, entry of water into the vinyl or leakage of water into the screed during construction. Had the floor finishing contractor completed the moisture test before applying the vinyl finish to the latex layer, it would have been possible to pin point the cause of the failure. But, with no reliable test results the problem can only be guessed to have been due to any one or more of these possible causes.

Conclusion

Always make sure that the moisture tests are conducted strictly on time using an accurate method and the results recorded prior to applying the final finish.