A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Under Floor Heating

Welcome to Screed Scientist’s latest section on Screeds for Under Floor Heating …

Right from the pattern of construction to the method of installation and maintenance, heated screeds differ significantly from normal screed constructions. Apart from being a cementitious or calcium sulphate layer containing the heating elements of under floor heating systems,’ the screed ‘plays a highly important role as a thermal conductor, improving the energy efficiency of the under floor heating system.

However, as the screed is generally installed over the plastic hot water pipes of the UFH system, chances are high for the screeds to develop issues of compaction around the pipes and develop problems due to the high movement potential of the screed owing to constant temperature change. It is therefore important to adopt adequate stress relief measures right at the design stage, and follow specific guidelines in order to obtain the best results from heated screeds.

As manufacturers and suppliers generally focus on the mechanical aspects of installation alone, these important considerations tend to be overlooked, resulting in screed disruptions and poor serviceability.

It is to help provide the necessary guidance and eliminate such screeding issues that Screed Scientist has specifically introduced this new section dedicated entirely to screeds for under floor heating systems. Our friendly UFH man will provide advice and tips on best practices and recommendations based on the relevant British or European standards. And, if you have any specific questions relating to your project, please feel free to ask our UFH man, and he will be happy to assist you with the solution, as quickly as possible.

Screed construction for under floor heating systems: Starting right from the basics…

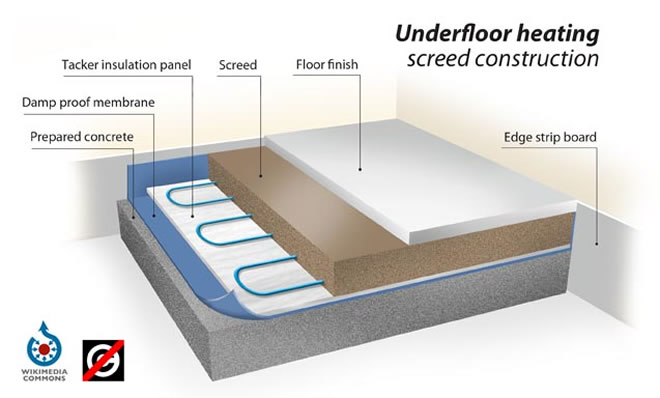

Now, before we go into the details, let us start right at the beginning with a simplified explanation of the screed construction for under floor heating systems using hot water pipes as the heating elements. The basic screed construction for under floor heating systems generally follows the ‘floating’ screed construction, where a Damp Proof Membrane (DPM) and tacker insulation panels are laid over the concrete substrate before laying the heating elements of the under floor heating system. This is done to maintain energy efficiency and prevent heat from escaping to the base. All the external perimeters, edges and penetrations are also sealed with perimeter strip foam.

The heating elements are then fastened to the tacker boards and the screed is laid over them in such a way as to encase the heating elements. A cementitious screed should ideally be laid at a minimum overall thickness of 75mm and a thickness of at least 50mm over the heating elements. Calcium Sulphate based screeds can be installed at a thinner section, generally at 60mm with minimum cover of 30mm over pipes. The screed should then be allowed to dry for the stipulated drying period before installing the final floor finish.

This is the basic screed construction followed for under floor heating systems. For further details on DIN, BS EN specifications for the construction of heated screeds and tips on choosing the right type of screed, please go through our section on ‘Tips and Advice’.