The Pros and Cons of Manufactured Sand

Before we get into the advantages and disadvantages of manufactured sand, what exactly is manufactured sand? Manufactured sand is sand produced by crushing rocks, quarry stones or larger aggregates pieces into sand-sized particles. Natural sand, on the other hand is the naturally formed sand extracted from river beds. The Manufacturing Process Rocks or quarry stones […]

The Different Aggregate Options

Aggregates are inert, granular materials which form a major component of screed and concrete mixes. With urban expansion and environmental constraints putting a strain on the naturally occurring aggregate sources such as sand, gravel and crushed rock, the construction industry is now widely exploring other sustainable and economically viable resources, to meet their ever-growing demand […]

The components that make a good screed: A quick guide

Every detail right from the type of cement and grade of aggregate to the method of storage of materials, play a major role in determining the quality of a screed. Here are a few tips on getting the details right for cement-sand levelling screeds. Read more:

Checklist for onsite supervision for screeding Tips 4 – 6

Following on from Checklist for onsite supervision for screeding Tips 1 – 3 we present tips 4 -6. 4. Screed Mix Check that the raw materials and the mixing of screed are correct. The ideal mix proportion for normal cement/sand screeds is – 1:3 to 1:5 – that is 1 part Portland Cement ( which […]

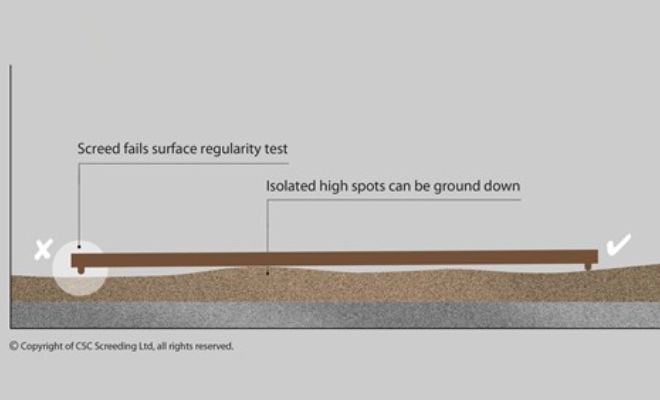

Surface Regularity of screeds for normal accuracy flooring

Surface regularity is generally defined as the limitation of deviation of the surface beneath a straightedge laid flat on the surface. As the measurement criteria varies for different types of screeds and flooring, it is important to ensure that the measurement is in compliance with the particular specification. Furnished here are the details of surface regularity measurement […]

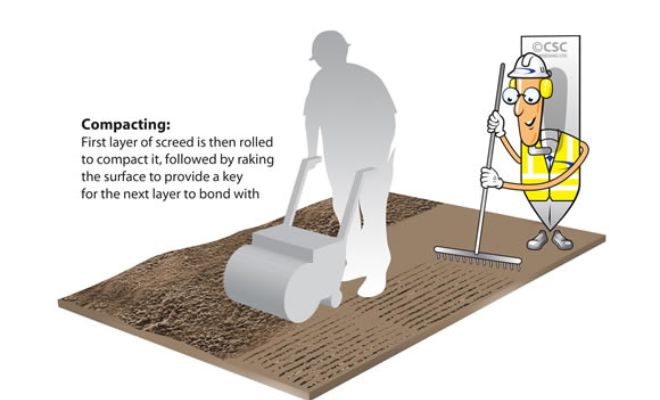

Checklist for onsite supervision for screeding Tips 1 – 3

From the verification of the screed specification to the installation of the screed and the adoption of screed protection measures, a successful screeding project requires meticulous attention and supervision at every step. Given here is a screeding checklist that will be useful in verifying all the important aspects of screeding at the work site. 1. […]

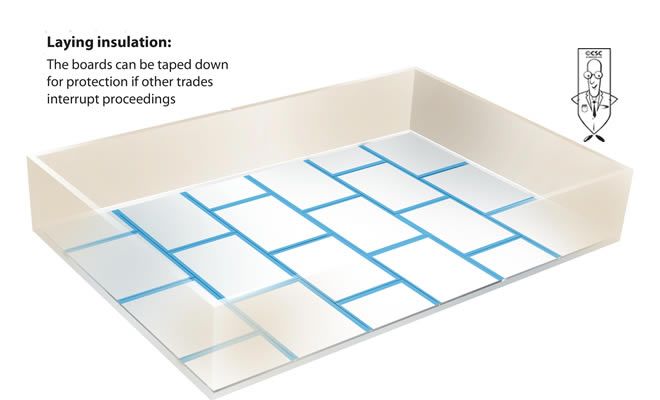

How to install rigid floor insulation on ground floor concrete substrates before screeding

The following information is a guide to the installation of rigid insulation on ground floors to receive a screed. The correct installation of polythene DPM, rigid insulation and separating layers are highly important not just for the overall integrity of the screed system but for the quality of the entire flooring. We have made an […]

The importance of flatness of concrete substrates for the installation of unbonded screeds

A flat concrete substrate is one of the most important pre-requisites for the application of unbonded screeds or floating screeds. The purpose of keeping a screed unbounded is to allow the screed to slip on a polythene membrane, providing a suitable screed construction for depths of over 50mm. Taking into consideration the fact that the screed will […]

Procedure for the mixing of screed using a screed pump

The quality of a screed is highly reliant on the method of mixing of the screed. Force action mixing of screeds using screed pumps is proven to yield screed mixes that are clearly superior in quality and homogeneity as compared to the usual screed mixes produced using free fall mixers. Given below are the steps […]

Tips on Choosing Screed Reinforcement

Screed reinforcement is a common practice adopted to improve the strength of screed constructions, curb shrinkage and cracking and impart better impact resistance to screeds. It is the inherent nature of screeds to shrink and curl and develop micro cracks during the process of drying. Reinforcement of the screeds using wire mesh or fibres can […]